Glass manufacturing dates back in 1500 B.C. in Egypt and Mesopotamia. The first natural glass was obsidian. The first glass makers gave shape to the soft glass by wrapping it around a core of sand or clay and then cooling it and removing the core’s material.

During the next decade, the glass manufacturing had a wider spread. The glass manufacturers learnt how to add various materials to the glass, in order to improve its strength, to achieve transparency or specific glass colour. Glass was mainly used by royal families or for religious ceremonies.

Around 300 B.C. some Syrian glass makers invented the glass blowing tube in multiple shapes and thicknesses. Romans brought the revolution in glass making at the 1st century A.C., with the use of several manufacturing techniques. Among them, there was the glass blowing in free shape and in mold, as well as the glass compression in mold. They also started to manufacture mirrors.

Along with the fall of the Roman Emperor, a big part of the excellent glass making art was lost. In Western Europe, the glass became again a product exclusively for the reach. The flat glass was used for the manufacturing of in vitro windows for the medieval churches. Around 650 A.C. the Syrian glass makers developed a revolutionary glass manufacturing method, the curved glass, which was used in windows until the end of the 19th century.

Venetians started to develop their own glass manufacturing at the end of the 13th century. They mastered a technique for the flat glass. All the glass manufacturing houses moved to the famous island of Murano and the Venetian techniques spread across Europe. Very soon, the French glass manufacturers evolved further the Italian techniques. In the meantime, glass manufacturing was mastered also in Germany, North Bohemia and England, where George Ravenscroft invented the lead glass in the decade of 1870. At about the same period French started the production of glass sheets.

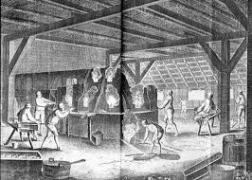

With the establishmen of the British Glass Company in 1773, England became the center of the world. Fearing competition, it forbade the glass manufacturing in America. However, the American revolution brought an inflow of European experience in the glass making. The first American innovation in glass manufacturing, was a glass press, which was patented as invention in 1825. The industrial revolution brought a number of innovations, starting by the development of the airpress in England in 1859. In 1871, William Pilkington invented a machine, which automatised glass production. This technique was improved in America by J. H. Lubber in 1903.

During the decade 1920-1930, the technique “pull” started to rule the glass manufacturing –flat glass with the best quality up to then-, resulting to the fall of prices in the whole glass industry.

Until 1929, 70% of the flat glass production in America, were supplied to the automotive industry. The biggest part of this production, were “security crystals”. The glass production changed forever, when Alastair Pilkington developed float, the modern glass technique in the 50’s. Today, 90% of the world flat glass is still produced with the use of the above technique.

In the 60’s the companies increased their production volume, while in parallel they decreased the prices of the flat glass. Until 1975 the float glass factories reached 97%. With the global energy crisis in the early 70’s, the demand for flat glass was reduced and the whole industry suffered. The situation got worse when Ford Motor Company started producing the float glass it need within its factories, a fact that significantly reduced the glass sales in automotive industry.

The glass manufacturers began to introduce new reflective coatings of high and medium yields concerning the transmission of visible light, solar radiation and shading coefficient. Moreover, new glass sheets were introduced, which made easier the curving of the flat glass for applications such as the aerodynamic design of cars. Additionally, the security glasses have combined different glass thicknesses in order to filter the various sound frequencies, while others have adopted the multiple sheet glasses in order to limit the noise pollution.

Another important area of interest in the glass industry for the next decade will be the electrochromic and photochromic technology, which allow the glass to perceive the light changes and be tunned accordingly. Today, 28% of the total of flat glass is used by the automotive industry. As an example, there is the evolution of the automatically adjustable mirrors in cars, which react in light changes by reducing the reflection while driving at night.

With the expansion of glass industry, the production volume surpasses the worldwide demand at about 1% yearly. The Asia-Pacific area continued its significant increase, which, up to 2002 constituted 50% of the worldwide flat glass production volume. Europe along with the total of America, will have enough production volume to cover their needs in glass. On the other side, the profit margins in China have been eliminated, as the sales price is almost equal to the production cost.

Professionals of glass production and processing have a unique business activity, offering a wide range of products to their customers, which they find attractive both in terms of aesthetics and functionality. Besides that, how many modern industries have a history of 3500 years? In order to continue their tradition and improvement of their products, it is necessary not to forget that this is a customer driven industry. Moreover, they have to know and satisfy the needs and expectations of customers worldwide. If they achieve that, they will definitely have constant success as industry.

Source:Democritus University of Thrace